Equipment: dryers, granulators and coating drums

Sector: Fertilizer (Morocco)

Context: Range of inspections prior to definition of maintenance plans

Services:

MODULE 4: Mechanical inspection of rotary equipment

MODULE 5: Inspection of tube mechanical alignment

MODULE 11: Static inspection of gear drive

SERCEM INDUSTRIE is well known in the field of heavy mechanics for 50 years in the suburb of Lyons in France .

Our customers are renowned international operators such as Lafarge- Holcim, Heidelberg, Alcoa , Rusal etc ..

They are all world leaders in the field of mining , cement & mineral chemistry .

Our knowledge is the mechanical improvement of production equipment such as rotary kilns , rotary dryers , mills, crushers etc…in France and abroad .

In this case, It concerns a range of inspections prior to definition of maintenance plans about several rotating drums in the field of fertilizer industry in Morocco.

CONTEXT: WE CARRY OUT AUDITS, DIAGNOSES AND RECOMMENDATIONS FOR THE CONSTRUCTION OF A MAINTENANCE PLAN

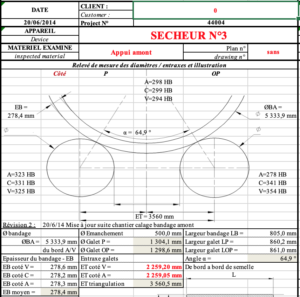

Module 5 . Alignment checks : (Equipment at standstill, no turn)

The position of the shell centers at the supports,

Mechanical Inspections: The position and parallelism of the axes of the rolling elements, which requires measuring :

- Drum slope,

- Chassis and inter-chassis slopes,

- Rollers slopes,

- Wheel spacing and turning angle of the rollers

- Ø and shapes rollers / tires

- Thrust position,

- Up and down movement and respective positions of the rolling element

Module 11 . Girth gear & pinion static inspection

Module 4 : Mechanical Condition

- Sliding

- Temperatures : shell,tyres,rollers,bearings

- Tyre runout

- Pad condition

- Seats of rollers / tyre

- Sealing of bearings

- Orientation of steering angles

- Presence of graphite blocks

- Roller and tyre cone

Following the audits carried out and the data collected, we provided the client with a precise diagnosis including recommendations for works to be carried out in the short and medium term.